Under Extrusion #

When your print does not come out as expected and there is not enough plastic extruded this is referred to as under extrusion. This can be caused by many different things on your printer. Some issues could be related to improperly setting up firmware settings to physical issues with the printer. We’re going to cover some common types here and go over how to resolve them.

Firmware and/or Slicer Issue #

One of the most common issues is a print that has holes and a uniform under extrusion throughout the entire print. This can be caused by improperly set esteps (usually if you have changed out your extruder), filament diameter setting in the slicer, turning on volumetric extrusion in firmware, or too low of a flowrate in the slicer.

Filament Diameter (Slicer) #

In your slicer, there is a setting for each printer to tell the slicer what diameter your filament is. If your printer profile is set to 2.85/3mm filament when you really have 1.75mm filament this will cause it to under extrude.

Flowrate (Slicer or Firmware) #

In your slicer and on your printer settings there are options to set the flowrate. This controls the amount of filament that is to be extruded on an extrusion move. Setting this too low will result in not enough plastic being extruded.

ESteps (Firmware) #

In your printer firmware, there is a setting called ESteps that tells the motor how many “steps” the motor needs to move to feed 1mm of filament. This setting usually needs to be changed when you change out your extruder for a different one. The best thing to do is refer to your extruder manufacturer documentation to see what their recommended esteps are for your printer. Our Unified firmware has a CUSTOM_ESTEPS setting that allows you to enter in your own value that overrides the stock setting for any printer.

If you are not sure what the esteps should be you should set the esteps to 100 and then calibrate with our tool here: EStep Calculator. It is recommended to put your estep value in the firmware as resetting the EEPROM will cause the firmware to revert back to the stock setting.

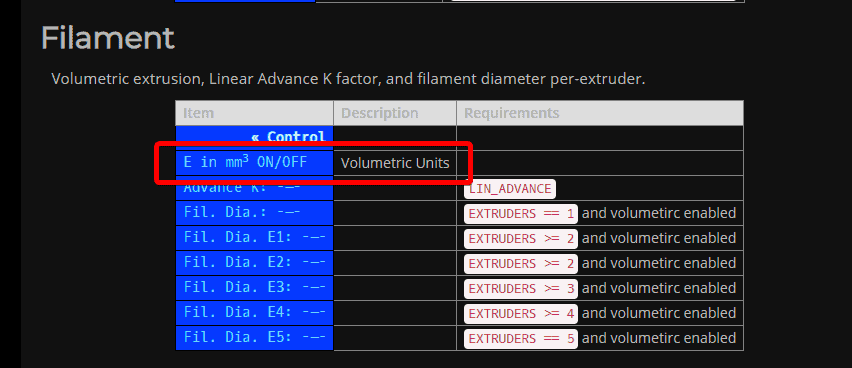

Volumetric Extrusion (Firmware) #

In Marlin, there is an option called Volumetric extrusion that changes how the filament is extruded. Most slicers do NOT use this. On the printer LCD, you should open the Filament menu and look for “E in mm3”. This should be set to OFF. If you are using our Unified 2 firmware this is already disabled at the firmware level to prevent users from accidentally turning it on.

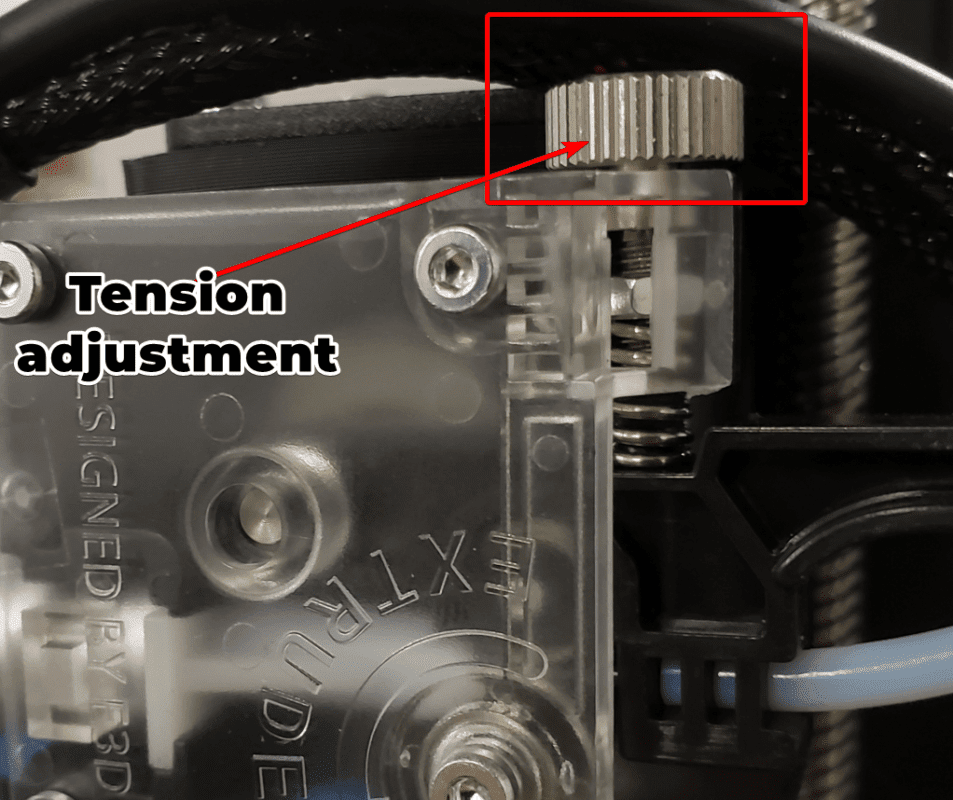

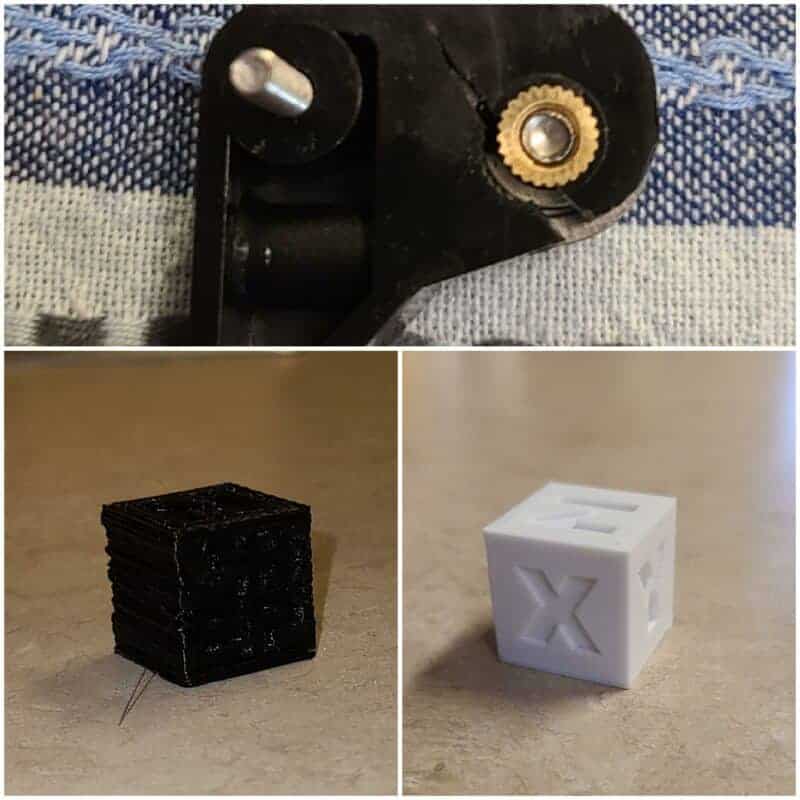

Extruder Tension/Defects #

The assembly that attaches to your E stepper motor is called the extruder. This has gears that bite into the filament to feed it to the hotend. Most of these extruders have springs on them and bearings. Some extruders (like Creality plastic ones) are notorious for cracking and causing under extrusion.

You should inspect your extruder for physical defects that would prevent it from feeding the filament in with proper tension.

Some extruders come with adjustments to increase or decrease the tension that is applied to the filament. It is important to note that you should NOT always have the tension set to the maximum setting as this can flatten out the filament and cause it not to feed correctly.